商務電話 (03) 271-3560

產品 Products

STM Solution for Semiconductor Industry

(Storage Transfer Management)

半導體載具搬運儲存解決方案

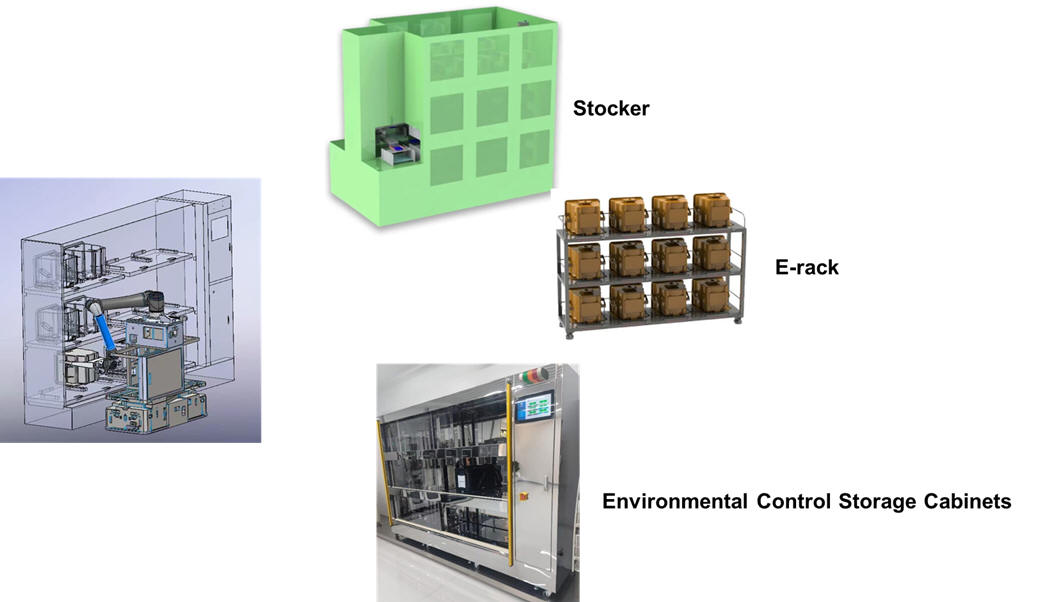

Types of Storage Systems for Wafer Carriers

Based on the image you provided, here are different types of storage systems for wafer carriers, along with their features and applications:

-

Automated Stocker:

- Main Function: Automated storage and management system for wafer boxes, focusing on efficient retrieval and space utilization.

- Environmental Control: Typically lacks precise environmental control, mainly provides a clean environment.

-

E-rack (Electronic Rack):

- Main Function: Electronic storage rack for small-scale or temporary storage needs.

- Environmental Control: Generally lacks environmental control, mainly for general storage requirements.

-

Environmental Control Storage Cabinets:

- Main Function: Provides controlled temperature, humidity, and gas (N2/CDA/XCDA) environments, suitable for long-term and sensitive storage needs.

- Environmental Control: Equipped with precise environmental control functions to ensure optimal storage conditions.

We provide all.

Features

The Necessity of Automation in Wafer Carrier Handling and Management in the Semiconductor Manufacturing Industry

In the semiconductor manufacturing industry, the automation of wafer carrier handling and management has become an important trend. This is not only to improve production efficiency but also for several other considerations. Below is a discussion on the necessity of automation in wafer carrier handling and management:

-

Enhancing Production Efficiency

- Reducing Human Errors: Manual handling of wafer carriers is prone to operational errors, such as incorrect placement, sequence errors, etc. These errors can affect the smoothness of the production process and the quality of the products. Automated systems can significantly reduce the occurrence of these errors.

- Increasing Handling Speed: Automated handling systems can complete a large amount of wafer carrier handling work in a short period, significantly improving production efficiency and shortening the production cycle.

-

Ensuring Product Quality

- Stability and Consistency: Automated handling systems can ensure the stability and consistency of each handling operation, avoiding issues such as shaking and collisions caused by improper manual operations, thereby reducing the risk of wafer damage.

- Reducing Contamination: Automated systems typically operate in cleanrooms and can better control environmental conditions, reducing the impact of external contaminants on wafers, ensuring high purity and high quality of the products.

-

Reducing Labor Costs

- Saving Human Resources: Automated systems can replace humans in performing highly repetitive and labor-intensive handling tasks, saving a large amount of human resources and freeing personnel for more creative work.

- Lowering Labor Costs: With rising labor costs, automated handling systems can reduce operational costs for enterprises, improving overall economic efficiency.

-

Improving Safety

- Reducing Work Injury Risks: Wafer carriers are usually heavy and need to be handled in high-precision environments. Manual handling poses certain work injury risks. Automated systems can reduce workers' involvement in high-risk operations, enhancing workplace safety.

- Stable Handling Process: Automated systems can handle wafer carriers in a more stable manner, avoiding damage and dangers caused by shaking and falling.

-

Supporting Smart Manufacturing

- Data Tracking and Analysis: Automated systems typically integrate Internet of Things (IoT) technology, enabling real-time tracking of each wafer carrier's handling process, collecting and analyzing relevant data, providing strong support for production management and optimization.

- Integration with Other Systems: Automated handling systems can seamlessly integrate with Warehouse Management Systems (WMS), Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) systems, etc., achieving full automation and intelligence of production processes.

Low-Cost Transport Robot

經濟型搬運機器人

|

Characteristics◆Intelligent lifting: The L series robots have a lifting function and can autonomously identify shelves and perform lifting and placing operations to achieve unmanned material handling. ◆Production system connection: Supports quick connection with EMS, ERP, and WMS systems, and supports the production system issuing tasks to robots. ◆RCS scheduling: supports multi-machine scheduling. Beside 150Kg, we also have models with a maximum load of 300 and 600Kg, please feel free to inquire. |

|

Machine size (L x W x H) |

740 x 500 x 1240 mm |

|

Maximum load capacity |

150 kg |

|

Empty vehicle weight |

76 kg |

|

Loading area |

700 x 600 mm |

|

Screen size |

10.1 Inches |

|

Minimum passing width |

70 cm |

|

Maximum speed |

1.2m/s |

|

Navigation |

Free navigation / Track navigation / Hybrid navigation / Follow |

|

Positioning accuracy |

10mm |

|

network |

4G / WIFI |

|

Battery |

Battery life 12H, charging 5H |

|

Certification |

CE / FCC / KC / NCC / EMC |

|

Expanded peripherals |

Elevator / Automatic door / Notification light and speaker / Pager / Follow-up cup / Roller / Box / Shelf |

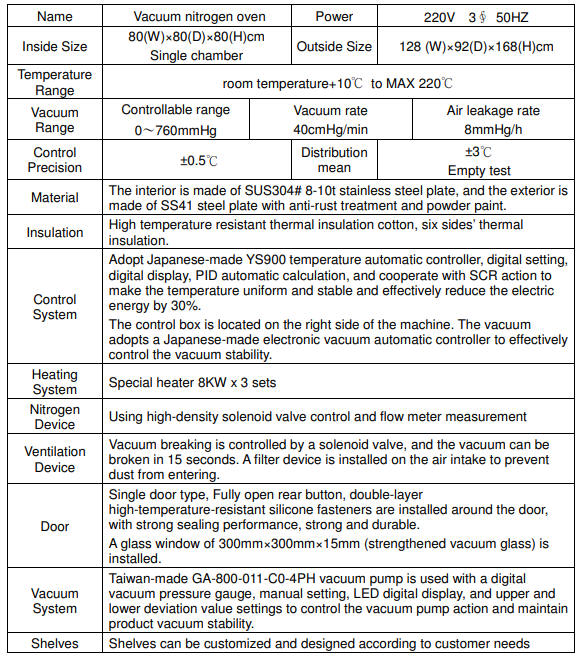

Vacuum Nitrogen Oven

真空氮氣烤箱

Features

1. Adopt Japanese-made YS900 temperature automatic controller,

digital setting, digital display, PID automatic calculation, and

cooperate with SCR action to make the temperature uniform and stable

and effectively reduce the electric energy by 30%.

2. Single door type, Fully open rear button, double-layer

high-temperature-resistant silicone fasteners are installed around

the door, with strong sealing performance, strong and durable.

A glass window of 300mm×300mm×15mm (strengthened vacuum glass) is

installed.

Specifications

Automatic Cartons Erector

自動開箱機

Features

1. Durable accessories

2. Used in conjunction with automated line or stand-alone machine

3. Save production time

4. Save labor

5. Improve efficiency

6. Safer

Specifications

|

Model CPK-60 |

Parameters |

|

Carton Opening Speed |

4-6 carton/min |

|

Carton Size |

L350-800,W250-600,H250-600mm |

|

Power Supply |

220v/380v50/60HZ |

|

Power |

240W |

|

Adhesive Tape Width |

60/72mm(choice

one) |

|

Carton Storage Quantity |

80-100pcs (1000mm) |

|

Air Consumption |

450NL/min |

|

Air Compressing |

5.5~6kg/cm³ |

|

Table Height |

800mm±25mm |

|

Machine dimension |

L2850 mm ×W2550 mm ×H1900 mm |

|

Machine Weight |

350Kg |

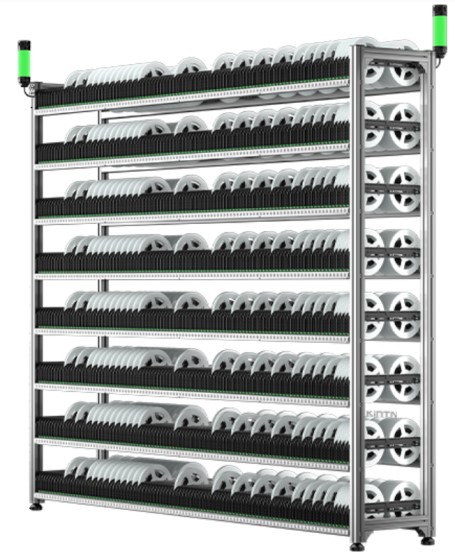

SMD Intelligent Electronic Material Rack

智能料盤貨架

Features

1. 1.5 Times comprehensively improve storage capacity

2. Immersive library location

3. Induction rack

4. Accurate detection

5. Flexible components

6. Static protection

Specifications

|

Model |

Working current |

Maximum Indicated location |

SIZE |

|

|

W-SMD2S-A8 |

100 indicator strips indicating storage

location ≤ 500mA |

Seven-color maximum total current ≤ 8200mA |

100 |

L2096 x W380 x H1920mm |

|

W-SMD2S-BS5 |

50 indicator strips indicating storage

location ≤ 500mA |

Seven-color maximum total current ≤ 2600mA |

50 |

L2096 x W380 x H1920mm |

|

W-SMD2S-BD5 |

100 indicator strips indicating storage

location ≤ 500mA |

Seven-color maximum total current ≤ 5200mA |

100 |

L2096 x W600 x H1920mm |

|

W-SMDC2S |

60 indicator strips indicating

storage location ≤ 240mA |

Seven-color maximum total current ≤ 2360mA |

60 |

L1296 x W380 x H1580mm |

|

W-SMD2N-A8 |

100 indicator strips indicating storage

location≤ 400mA |

Seven-color maximum total current ≤ 6600mA |

100 |

L2096 x W380 x H1810mm |

|

W-SMD2N-B5 |

50 indicator strips indicating storage

location≤ 400mA |

Seven-color maximum total current ≤ 2100mA |

50 |

L2096 x W380 x H1810mm |

|

W-SMD-C2N |

60 indicator strips indicating storage

location≤ 240mA |

Seven-color maximum total current ≤ 2360mA |

60 |

L1296 x W380 x H1590mm |

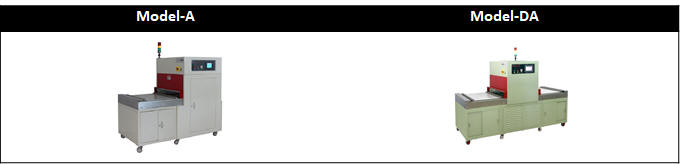

Automatic Protective Packing Machine

全自動瞬熱保護包裝機

Features

1.

Impulse vacuum rod heating method:

(1)

stationery type heating method for longer life of heaters

(2)

Impulse heating time control by (a) photo cell; (b) timer.

(3)

Reduce power consumption by 40% compares to traditional constant

heating method.

2.

Heater oven

(1)

Automatic vacuum protective packaging machine designed with

the best pattern by impulse vacuum tube heater arrangement to get

the best temperature distribution.

(2)

Stationery type heating oven for longer life of heating

rods.

Specifications

|

Model |

Working

Area (cm) |

Vacuum

motor |

Panel |

Photocell |

Heater |

Machine

Size (cm) |

|

SP-5580D |

55 x 80 |

2.2KW |

Touch

Screen |

Yes |

27KW |

224x91x144 |

|

SP-5580DL |

55 x 80 |

2.2KW |

Touch

Screen |

Yes |

27KW |

300x100x146 |

|

SP-5580A |

55 x 80 |

2.2KW |

Touch

Screen |

Yes |

27KW |

280x162x146 |

|

SP-7090D |

70 x 90 |

3KW |

Touch

Screen |

Yes |

30KW |

246x105x144 |

|

SP-7090DL |

70 x 90 |

3KW |

Touch

Screen |

Yes |

30KW |

300x105x144 |

|

SP-7090DA |

70 x 90 |

3KW |

Touch

Screen |

Yes |

30KW |

356x180x146 |

Automatic Vacuum Packing Machine

全自動真空包裝機

Features

1.

The only one specially designed for PCB & Electronic product vacuum

packaging with adjustable vacuum timing and pressure instead of food

vacuum pack.

2.

The stainless steel platform, it is convenient to put and take out

the packaging product.

3.

Install with safety photoelectric eye detective device in the

entrance of in and out feed.

4.

Can be operated by only one side for small quantity production or

both sides operation by turns. One machine applies for two options.

High productivity and no fall board issue.

5.

One pair of air cylinders are used to strengthen sealing. The

intensity that the vacuum does not influence sealing that at last by

setting vacuum pressure high and low before sealing. No matter how

much is packed, it is all subject to the setting of the vacuity and

guarantees the vacuum not too excessive vacuum to damage the vacuum

bag and to leak gas.

6.

Equipped with anti-slant device to prevent products tilted after

vacuum released.

Specifications

|

Model |

Working Area (cm) |

Sealing element |

Machine Size

(cm) |

|

VP-8060A |

80 x 60 x 11 |

81 x 2 |

170 x 100 x 158 |

|

VP-8060DA |

80 x 60 x 11 |

81 x 2 x 2 side |

246 x 95 x 162 |